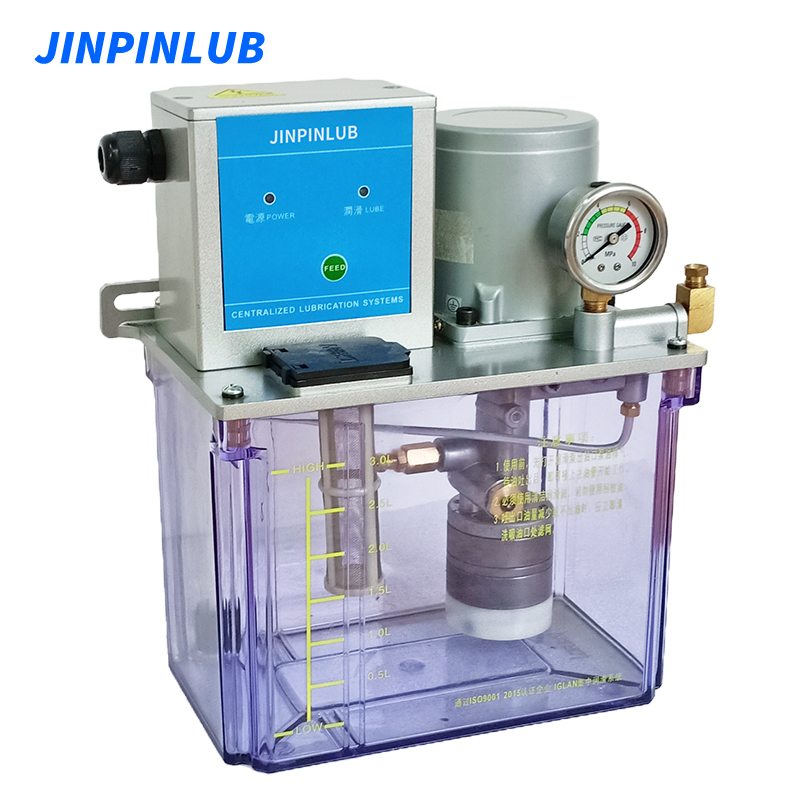

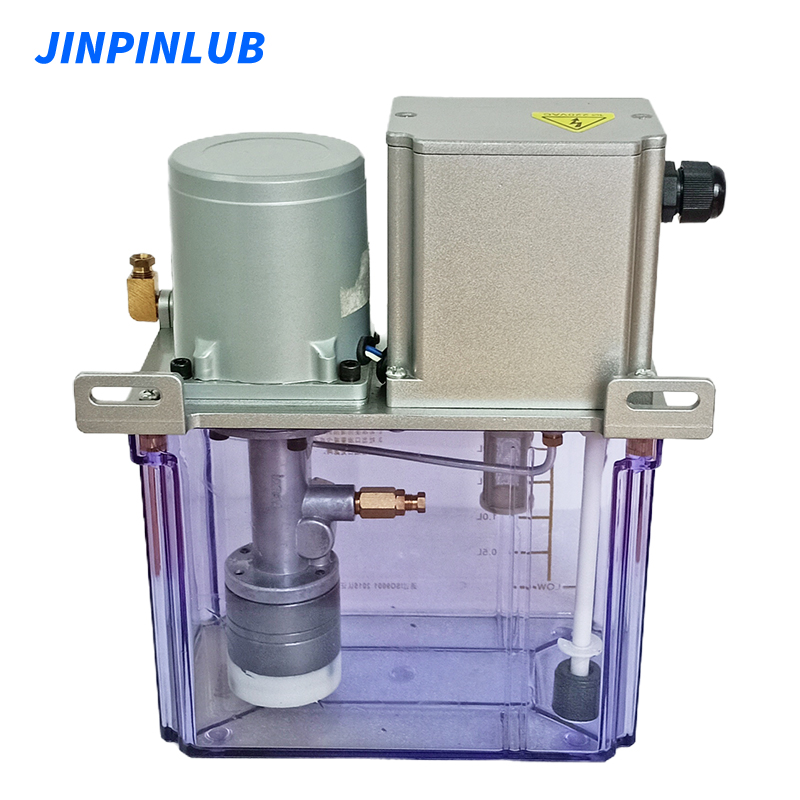

JMT4 Positive Displacement Pressure Relief Lubrication Pump

JMT4 is a positive displacement electric lubrication pump with multiple capacities, including 3L, 6L, 4L, 8L, 20L, etc. It is driven by an induction motor, provides stable output pressure, can work for a long time, and outputs a large flow of lubricant.

Description

Features

1. The lubrication and interval time of the lubrication pump are controlled by the PLC of the host.

2. The lubrication pump can be equipped with a pressure switch to detect whether the oil circuit is damaged.

3. The lubrication pump is equipped with a floating switch to detect the oil level and automatically send a signal.

4. The pump is equipped with a pressure gauge by default to detect the operating pressure of the oil pump.

5. The lubrication pump is equipped with a forced lubrication button and a lubrication working indicator light.

6. The lubrication pump is driven by a grinding gear pump with an induction motor, with stable pressure, low noise, durable and reliable.

7. The JMT4 model is a volumetric lubrication pump, which needs to be used with a volumetric distributor to achieve a quantitative oil supply effect.

Specification

| Model | JMT4 |

| Lubrication time | PLC |

| Interval time | PLC |

| Operating temperature | -10℃~ +60°C (Low temperature conditions require antifreeze grease) |

| Number of outlets | 1 |

| Reservoir capacity | 3L(Resin tank), 4L, 6L, 8L, 20L (Metal tank) |

| Refilling | From top |

| Lubricant | 32-68cSt@40℃ |

| Motor power | 40W |

| Discharge | 250 mL/min |

| Max. operating pressure | 2.3 MPa |

| Connection thread | Outlet Φ6 |

| Operating voltage | 110VAC, 220VAC, 12VDC, 24VDC, 3~ 220V, 3~ 380V, 3~ 440V, 3~ 460V |

| Certification | CE |

| Low level switch | N.C. contact |

Precautions

1. Please carefully confirm the voltage of the lubrication pump and connect the appropriate power supply.

2. The lubrication pump must use clean oil, and recycled lubricating oil is not allowed.

3. It is recommended to refill the lubricating oil to the oil level line each time.

4. It is recommended to clean the oil reservoir once every two months, and clean or replace the filter basket and oil filter at the oil inlet.

5. The increase in the running time of the lubrication pump can increase the total lubrication amount of the lubrication system, and the reduction in running time can reduce the total lubrication amount of the lubrication system.

6. After the lubrication system is installed or after disassembling and replacing parts, the air in the lubrication system should be discharged first.

7. After the lubrication pump is powered on, it is not allowed to open the cover on the top of the pump to prevent the risk of electric shock.